Precision in prototype design enables tech startups to transform innovative ideas into reliable, scalable products right from the outset. Consistent accuracy helps teams avoid costly rework, shortens development cycles, and ensures their prototypes meet both compliance standards and user expectations. This attention to detail is not optional, especially when minor miscalculations might lead to setbacks that new companies can ill afford.

The Critical Role of Prototypes in Tech Innovation

Prototypes perform a vital function in the tech sector by serving as the first tangible versions of an idea. They convert abstract concepts into models that can be tested, evaluated, and improved.

Through prototypes, teams detect design challenges early. This is why many design professionals explore how to use prototyping to identify design problems early – it helps avoid critical errors before major investments are made.

A precise prototype is crucial when presenting solutions to investors or stakeholders. Accurate builds demonstrate feasibility and give confidence that the project is grounded in reality rather than theory.

For manufacturing partners, a detailed prototype communicates essential specifications and design intent. This reduces misunderstandings and limits rework during the production phase.

In practical terms, successful prototypes bridge the gap between vision and execution. For startups wondering how to create better prototypes, it often begins with tighter tolerances and more deliberate iteration cycles.They provide a clear standard that moves the project towards a viable product, aligning the efforts of designers, engineers, and business leaders alike.

Why Startups Can’t Afford to Get Measurements Wrong

In sectors such as medtech, robotics, and IoT, even minor inaccuracies during prototyping can cause components not to fit, sensors to misread, or systems to fail outright. For startups, these errors often result in increased costs, delays, or in the worst cases, failure to reach the market.

Accurate measurements are essential at the prototyping stage, which is why many industrial designers collaborate with services like the Irish company Calibration Lab to calibrate testing instruments early on. Missteps in measurement can lead to faulty medical devices or unreliable robotics, directly impacting user safety and regulatory approval.

Startups typically operate with limited resources and tight timelines, making costly rework particularly damaging. The smallest dimensional error can force a redesign, pushing back deadlines and depleting budgets quickly.

Misaligned mechanical components in a wearable, for example, could compromise its durability or cause user discomfort. Similarly, poor tolerances in IoT hardware can leave devices open to environmental damage or decreased performance, reducing customer trust and satisfaction.

Precision as Part of the Startup’s Risk Management Process

For tech startups, the risk management process extends well beyond simple financial calculations. Inaccurate prototypes can easily introduce hazards, making products less safe for users and more vulnerable to operational issues.

Failing to prioritise precision may result in prototypes that do not meet legal or industry standards. This can expose the startup to increased liability, legal consequences, or regulatory fines. The risk of failing compliance audits becomes much higher when early-stage prototypes are not built to specification.

Mistakes that seem minor at the prototype stage can escalate into significant challenges as the product moves closer to market. Errors left unaddressed may lead to costly redesigns, production delays, or complete product recalls.

When safety, certification, and investor trust are on the line, incorporating precision into your risk management process is a strategic move – not just a technical one. Startups that bake accuracy into their prototypes improve their chances of passing certification and inspection stages.

By making precision a cornerstone of prototyping, startups are better positioned to identify weaknesses before they become liabilities. This reduces not only risk but also helps maintain investor confidence throughout the development cycle.

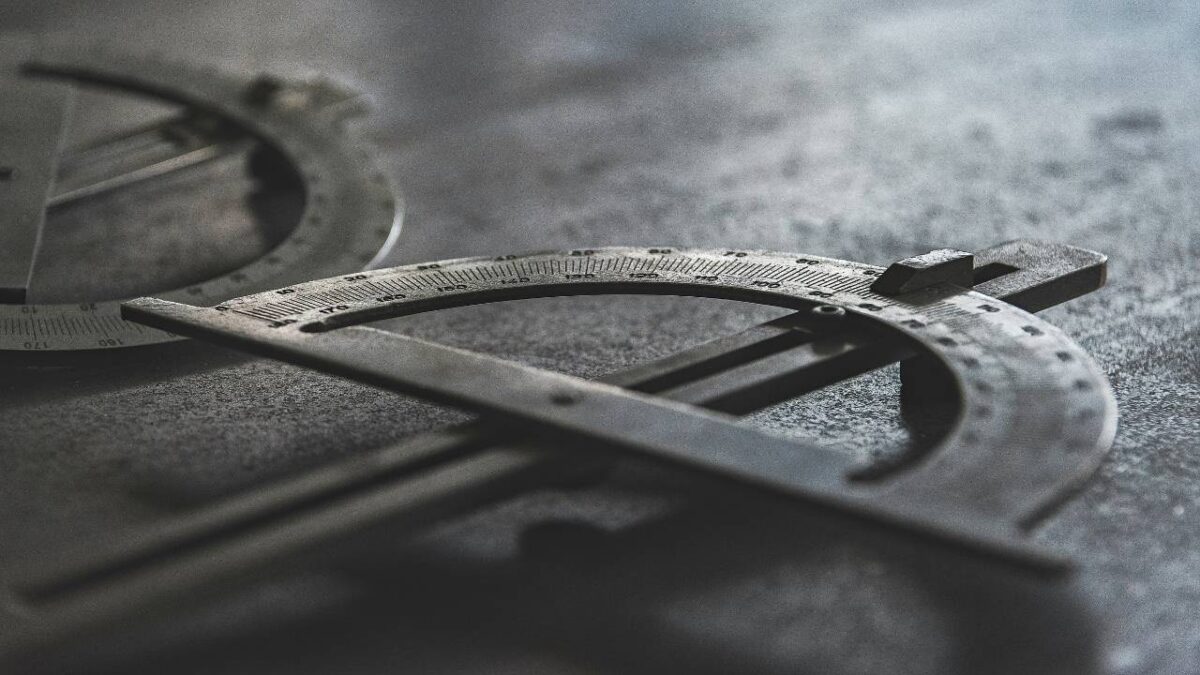

The Overlooked Importance of Equipment Calibration in Design Studios

Design studios often prioritise rapid iteration and creative experimentation. However, even minor issues with poorly calibrated laser cutters, 3D printers, or measurement gear can quietly undermine the precision of prototypes, resulting in misaligned parts or inconsistent outputs.

When tolerances matter, the difference between a reliable prototype and a problematic one can be traced back to how precisely each piece of equipment is tuned. Mismatches in calibration lead to measurement errors that impact both fit and function.

From micrometres to multimeters, every tool influences the result. That’s why equipment calibration should be a non-negotiable step in every design team’s workflow.

Ignoring regular calibration can introduce repeated flaws during the build process, subtly eroding trust in both the prototype and the tools themselves. Early identification and correction of these issues help prevent wasted materials and reduce avoidable delays.

Establishing a consistent calibration routine means greater control over build quality. In turn, this allows teams to achieve designs that match expectations and specifications with higher confidence.

Scaling from Prototype to Production: Why Accuracy Matters Even More Later

When a tech startup moves from prototype to full production, precision becomes even more important. Small errors in the prototype phase can lead to much bigger issues during large-scale manufacturing. A minor miscalculation early on might result in thousands of faulty units later.

Investing in accuracy at the prototype stage helps companies avoid costly redesigns and production delays. Manufacturers rely on precise specifications to produce components that fit and function as intended. Even slight inaccuracies can disrupt assembly lines, leading to wasted materials and increased operational costs.

Quality assurance processes benefit from early precision as well. Clear and accurate documentation makes it easier to identify defects and enforce standards throughout production. This can help prevent defective products from reaching customers.

Accurate prototypes also streamline the logistics of shipping. Precise dimensions and tested designs reduce the chances of products being damaged in transit. This lowers the risk of returns and improves customer satisfaction.

By focusing on precision from the beginning, tech startups can make scaling up both smoother and more cost-effective. Reliability established early can be maintained throughout the production and delivery process.

Conclusion

Precision goes beyond simple accuracy; it reflects a methodical approach that supports consistent quality and builds trust in a product’s functionality. Startups that commit to precise prototyping are more likely to meet regulatory requirements, reassure stakeholders, and position themselves for scalable growth. By recognising the value of meticulous execution, they enhance their chances of delivering reliable and market-ready technology.